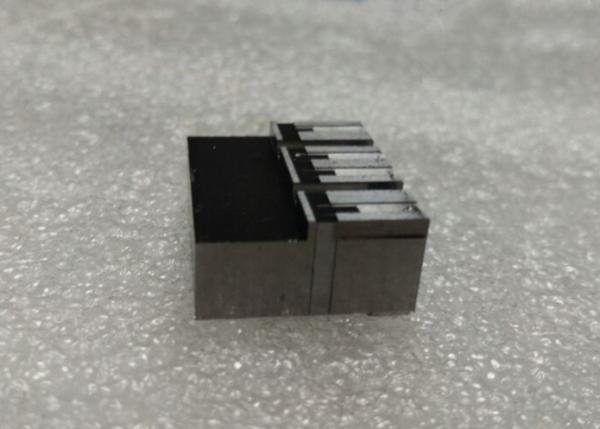

Tungsten Steel Progressive Die Stamping Texture Surface Ra0.4um

Roughness

Cutting Process Progressive Die - Stamping Single Punch , Roughness

ra0.4um

Our advantage:

Slow wire cutting technology:

The development level of CNC slow wire cutting technology has been

quite high, the function is quite perfect, and the degree of

automation has reached the level of unattended operation. The

maximum cutting speed has reached 300mm2/min, the machining

accuracy can reach ±1.5μm, and the machined surface roughness Ra is

0.1~0.2μm. The development of the fine wire cutting technology with

a diameter of 0.03 to 0.1 mm enables one-time cutting of the

concave-convex mold to be completed, and the cutting process of a

narrow groove of 0.04 mm and a round radius of 0.02 mm can be

performed. Taper cutting technology has been able to perform

precision machining with taper of 30° or more.

Product Information:

List of Equipment for punching business

| NO. | Workshop | Name of equipment | Specification |

1

| CNC automatic workshop | punching machine | high speed punching machine |

middle speed punching machine |

general punchingmachine |

| 2 | Single-die workshop | punching machine | Manual single punch machine |

| 3 | mould workshop | line cutting machine | CNC line cutting machine |

| 4 | Material split workshop | Material split | Semiautomatic material split |

| 5 | Material split workshop | vacuum quenching furnace | special for 65Mn steel |

| Line cutting machine for make mould |

Surface Treatment:

Wire-cutting, Zn- Plated, Ni-plated, Passivated,Tin-plated,

Sandblast and Anodize, Polish, Electro Painting, Powder coating,

Chrome plated, Smooth, etc.

Shipping ways :

1. Fedex / UPS / DHL / TNT for little weight goods

2. By air or by sea for heavy goods

3. Customers' forwarder

Delivery Time: 3-10 working days, depends on the quantity and

drawings requirements

Design Software:

2D: dxf&dwg&pdf

3D: UG&PROE&Auto CAD